Have you considered LEV?

Have you considered LEV?

What is LEV? LEV is Local Exhaust Ventilation! Thousands of employees across the UK each year are made ill by contaminants they were breathing in at work, despite using extraction and masks. The Health and Safety Executive concluded that the controls of LEV and masks were not controlling exposures.

The HSE thought very hard about why LEV failed to control exposures and published very specific legally enforceable guidance which imposed duties on employers, users, designers, and testers of LEV.

Last year there were around 200 new cases of occupationally caused asthma and 13,000 cases of breathing problems and respiratory disease made worse by work.

About 8 000 cancer deaths and 13 500 newly diagnosed cancer cases each year could be due to work. 90,000 claims for industrial disease compensation were made in the last 12 months. The estimated cost to the British Industry is over 3 billion pounds per year.

The typical local exhaust ventilation system comprises of a:

Hood.

Duct.

Filter.

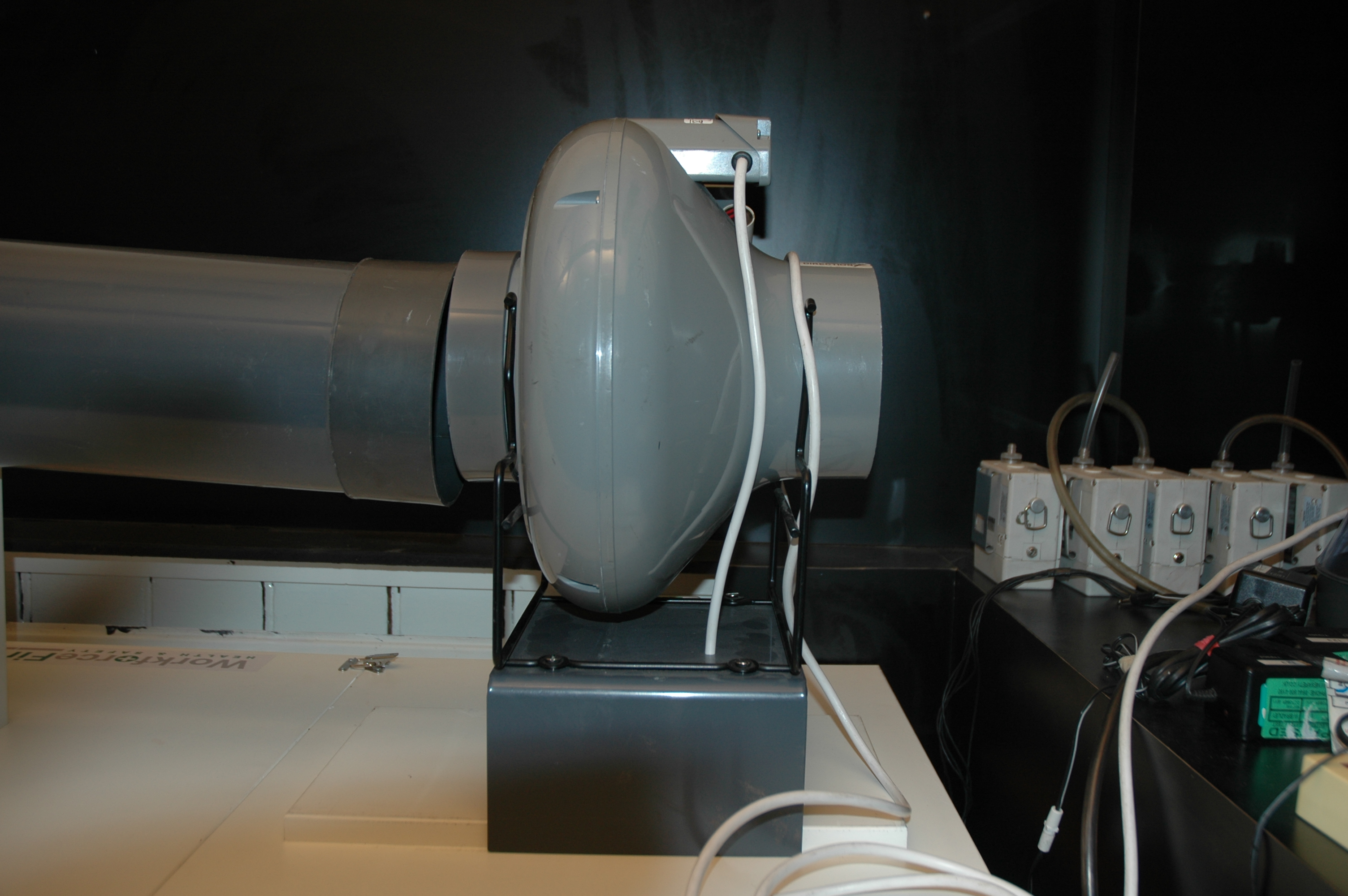

Fan.

Exhaust.

The hood is the key design feature. Hoods may vary in size from tiny on-tool extractors to walk in enclosures which enclose the process and emissions. Hoods may be receiving hoods which contain and remove moving contaminants or they may be capture hoods which use airflow to re-direct the contaminant into the hood.

Bag filters for dust, cyclones, electrostatic precipitators, wet backed booth, panel filters, and solvent charcoal filters. All filters offer resistance to airflow. Generally the dirtier they are, the more resistance they give. It is vitally important that filters continue to work efficiently when air is returned to the workplace.

The exhaust of the system is where the air is blown out of the system. In a dust filtration system, the exhaust may be through a HEPA filter, into the workplace. The duct that exits the building to discharge to the atmosphere is the stack. This usually has to be high enough for the air to clear the apex of the building. LEV is used in many working factories that produce, manufacture or distributors’ materials that come in the form of vapors, mists or liquids. But also establishments such as kitchens would also use LEV.